Skill of grinding inner hole of louver wheel

Time:2023-12-04 03:09:21 Author:admin

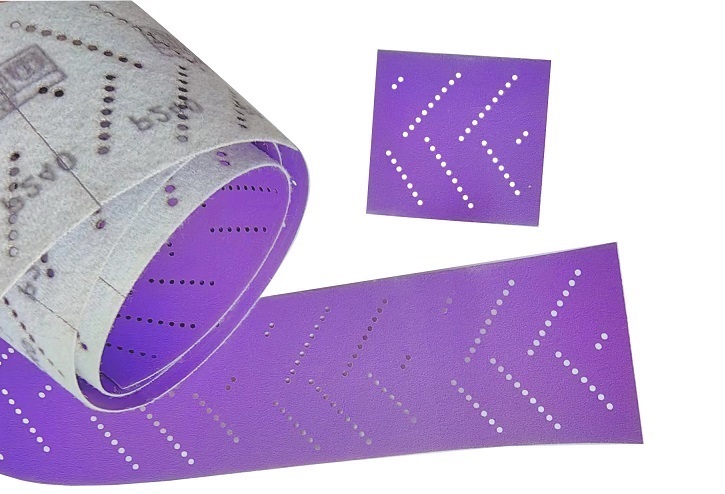

According to different technological purposes and requirements, there are many grinding methods for louver wheel, the main purpose is to cut off the surplus material on the workpiece. So what should be paid attention to when grinding the inner hole of discontinuity surface with louver wheel?

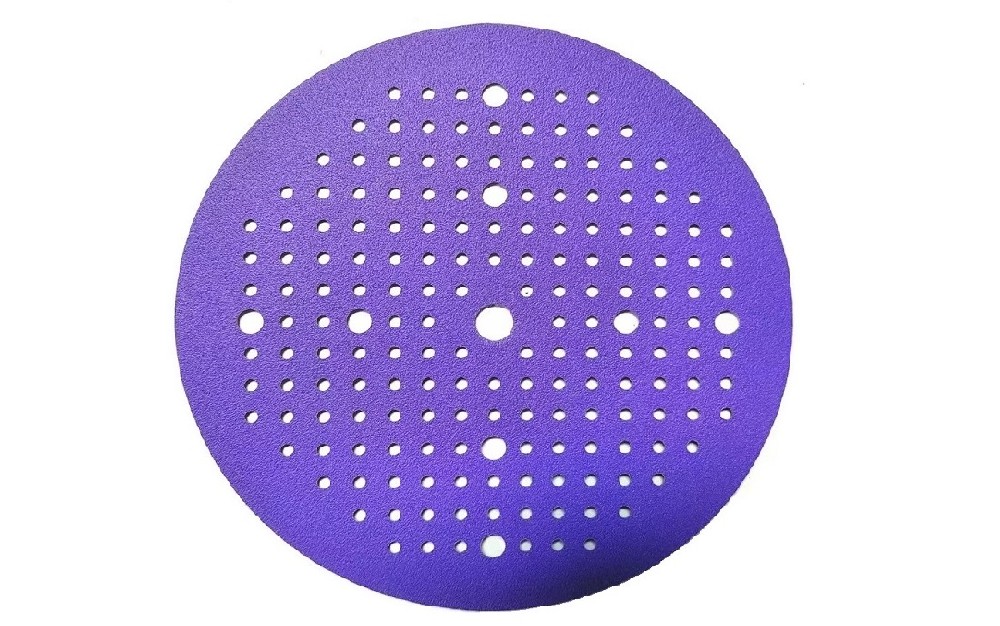

1. When there are wide grooves, keyways or radial through holes on the surface of the inner hole, due to the discontinuous contact between the impeller and the hole wall in the grinding process, the shape error of the inner hole is easy to occur, so corresponding measures must be taken.

2. When grinding a wide groove hole on the inner hole surface, it is easy to produce bell mouth at both ends of the wide groove. The measures to be taken are as follows: use the extended shaft with larger diameter as far as possible, properly increase the width of the shutter wheel, and trim the shutter wheel with diamond in time.

3. When grinding the hole with keyway on the inner hole surface, it is easy to produce "collapse angle" at the edge of keyway. At this time, the diameter of the impeller can be appropriately increased, the width of the impeller can be reduced, and the stiffness of the extended shaft can be increased. For the inner hole with high precision, hardwood or bakelite can be embedded in the keyway before grinding the inner hole.

4. When grinding radial through-hole on the surface of inner hole, polygon is easily formed on the hole wall. At this time, it can be prevented by properly increasing the diameter of the louver wheel, using a rigid material as the extension shaft, and timely trimming the shutter wheel. In order to ensure the machining accuracy and surface roughness of the hole, the back cut should be reduced and the number of "smooth grinding" should be increased appropriately .