Tips for using a flap disc

Tips for using a flap disc

Flap disc, also known as polishing wheel. Flap disc is a common polishing tool in daily life, mainly used for rust removal, deburring, and polishing of weld seams on the surface of workpieces. Today, DaFei Abrasives will teach you a few tips for using a flip disc, which can improve grinding efficiency and extend the service life of the louver blade

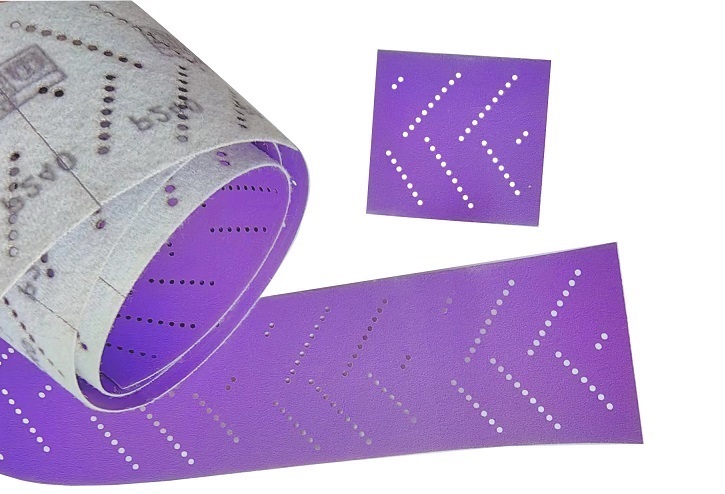

1. Choose a suitable flat disc for the appropriate grip. If you want to achieve a smooth surface, choose a finer grit size (80 or 120 grit). If the rust spots on the surface of the workpiece are stubborn or if polishing efficiency is desired, it is necessary to use coarser abrasives (40 mesh or 60 mesh).

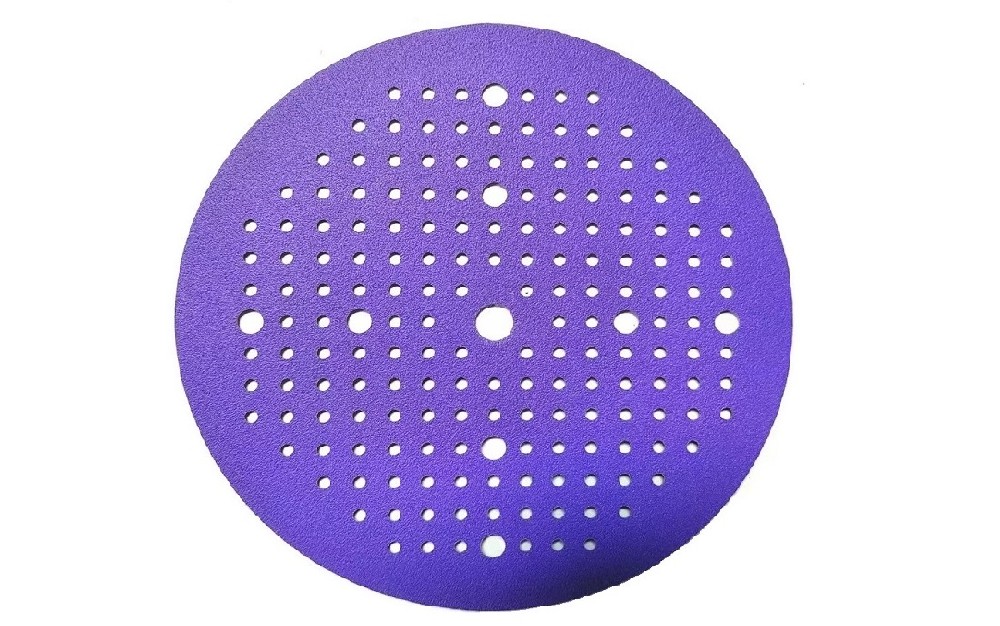

2. When polishing, choose the appropriate angle. A flat disc is suitable for working at a fixed angle, which reduces the amount of grinding surface it comes into contact with and slows down its wear. When polishing on a flat surface, it increases the number of grinding surfaces it comes into contact with and accelerates its wear. When using a flip disc, selecting an angle of approximately 5-10 degrees ensures optimal contact with the workpiece and prevents excessive wear.

3. When polishing, the operator's strength should also be controlled. Avoid applying too much or too little pressure. Excessive pressure can cause the flash disc to overload, and excessive heat can lead to faster wear of the louvers, while reducing the effectiveness of the abrasive. But if insufficient pressure is applied to the flash disc, it will not achieve effective grinding effect and will also prolong the grinding time.

Mastering the above three techniques can help you fully unleash the potential of a flash disc and achieve better polishing results.